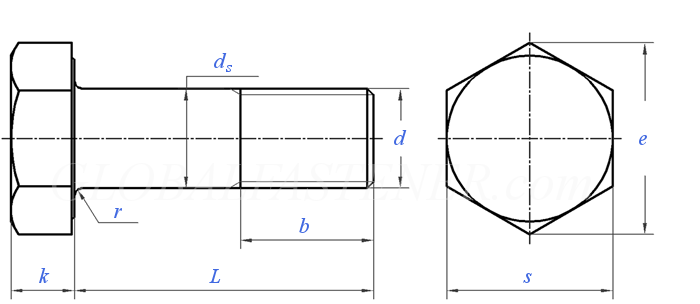

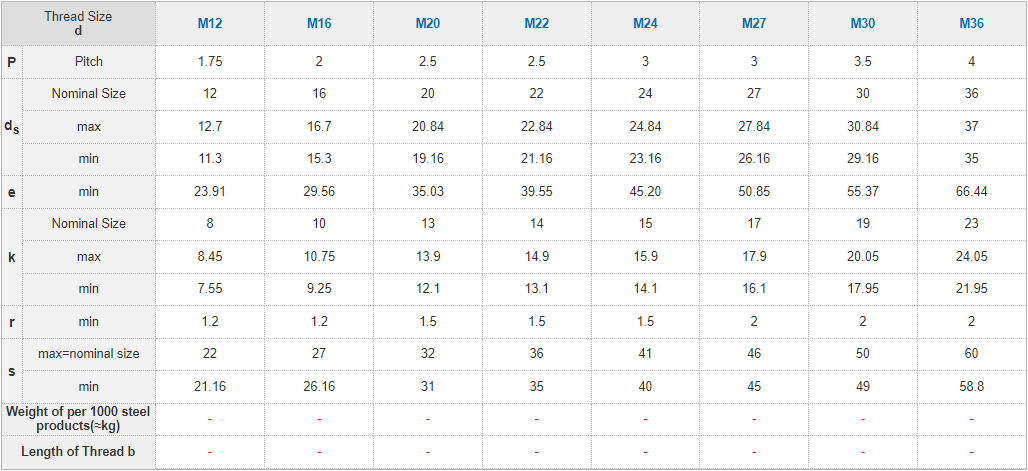

Igama lemveliso: I-Hex Structural Bolt / Heavy Hex Bolt

Ubungakanani: M12-36

Ubude: 10-5000mm okanye njengoko kufuneka

IBakala: Uhlobo 1, iGr.10.9

Izinto: Intsimbi/20MnTiB/40Cr/35CrMoA/42CrMoA

Umphezulu: Mnyama, HDG

Umgangatho: ASTM A325/A490 DIN6914

Isiqinisekiso: ISO 9001

Isampulu: Iisampuli zasimahla

Ukusetyenziswa: Izakhiwo zentsimbi, imigangatho emininzi, isiseko sentsimbi esiphakamileyo, izakhiwo, izakhiwo zemizi-mveliso, indlela ephezulu, umzila kaloliwe, umphunga wentsimbi, inqaba, isikhululo samandla kunye nezinye izakhelo zeworkshop yokwakha.

I-DIN 6914 - 1989 iiBolt zeHexagon eziphakamileyo ezinobubanzi obukhulu kuzo zonke iiFlethi zokuBolitha kwesakhiwo

① Izinto:Intsimbi, iklasi yamandla 10.9 yiDIN ISO 898-1

Masiqale siqonde ukuba yintoni isakhiwo sentsimbi ephezulu yokuqina.Ngokuqhelekileyo yenziwe ngentsimbi ephezulu yokushisa (35CrMo\35 carbon steel material, njl.), Enokwahlulwa ibe ngamabakala angama-8.8 ngokwebakala lokusebenza.IBakala 10.9, ngokungafaniyo neebholithi eziqhelekileyo, iibholithi mazibe ngaphezu kwebakala 8.8.Akukho mfuneko yokubeka phambili iimfuno zebakala lensimbi kunye nenqanaba lentsimbi xa ukhetha.I-Friction joints isetyenziswa ngokubanzi kwi-steel structure engineering.

Isakhiwo sensimbi iibholiti ezinokuqina okuphezulu zinokwahlulwa zibe ziindidi ezimbini: ukudityaniswa kohlobo lwe-friction kunye noxinzelelo lohlobo loxinzelelo ngokweempawu zamandla.Umdibaniso womdibaniso we-bolt-high-power-bearing type connection idinga kuphela ukuba i-rust-proof.Nangona kunjalo, iibholiti zodidi oluqinileyo zinezibonelelo zonxibelelwano oluluqilima, amandla alungileyo, ukumelana nokudinwa, kwaye zilungele ukuthwala imithwalo eguquguqukayo, kodwa umphezulu woqhagamshelo kufuneka uphathwe ngobume bokukhuhlana, ngokubanzi ngokuqhushumba kwesanti, ukuqhushumba kwesanti, emva koko kugqunywe ngentsimbi. ipeyinti ye-zinc-rich-rich.

Ngenxa yokwahlukana kwesakhiwo se-bolt kunye neendlela zokwakha, iibholiti eziphakamileyo eziphezulu zezakhiwo zetsimbi zinokwahlulwa zibe ziindidi ezimbini: i-hexagonal head high-high-power bolts kunye ne-torsional shear type-high-power bolts.Uhlobo lwentloko enkulu ye-hex iyafana neebholiti zentloko ze-hex eziqhelekileyo.Intloko yebholithi yesikere se-torsion iyafana nentloko ye-rivet, kodwa isiphelo esinentambo sesikere se-torsion sine-collet ye-torx kunye ne-annular groove yokulawula i-torque yokuqinisa.Lo mahluko ufuna ingqalelo.

Ibhanti yokudibanisa ibholithi ibandakanya iinxalenye ezintathu: ibholithi, i-nut kunye newasha.Ulwakhiwo kunye neemfuno zokucwangciswa kweebholiti eziphezulu zamandla zifana nezo zebholiti eziqhelekileyo.Emva koko kufuneka isetyenziswe ngokweenkcukacha.Kuphela iibholiti eziphezulu zebanga lesi-8.8 zingasetyenziselwa iintloko ezinkulu zehexagon, kwaye iibholiti zokuqina eziphakamileyo zebakala le-10.9 zingasetyenziselwa kuphela uhlobo lwe-torsion shear iibholithi ezomeleleyo.

Ukulayishwa kwangaphambili kweebholiti eziphezulu kwizakhiwo zetsimbi kufezekiswa ngokuqiniswa kwamantongomane.Ukulayisha kwangaphambili ngokuqhelekileyo kulawulwa ngokujija umsila we-bolt usebenzisa indlela ye-torque, indlela ye-angle okanye indlela ye-Torx.

Ngoku kukho i-wrench ekhethekileyo ebonisa i-torque.Ukusebenzisa ubudlelwane phakathi kwe-torque elinganisiweyo kunye ne-bolt tension, i-torque isetyenziselwa ukufezekisa ixabiso elifunekayo loxinzelelo.

Indlela yekona Indlela yekona ihlukaniswe ngamanyathelo amabini, enye i-screwing yokuqala, kwaye enye i-screwing yokugqibela.Ukuyibeka ngokulula, ukuqiniswa kokuqala ngokuqhelekileyo kwenziwa ngumsebenzi usebenzisa i-wrench eqhelekileyo ukwenza amacandelo axhunyiwe ngokusondeleyo, kwaye ukuqiniswa kokugqibela kuqala ukusuka kwindawo yokuqala yokuqinisa, kwaye i-angle yokugqibela yokuqinisa isekelwe kwi-diameter ye-bolt. kunye nobunzima besitaki sepleyiti.Sebenzisa i-wrench eyomeleleyo ukujika i-nut kwaye uyijije kwixabiso le-engile esele imiselwe, kwaye ukuxinana kwebholiti kunokufikelela kwixabiso elifunekayo lokulayisha kwangaphambili.Ukuze kuthintelwe i-torque coefficient ye-bolts-high-power bolts ukutshintsha ngenxa yempembelelo yendawo yangaphandle, ukuqiniswa kokuqala kunye nokugqibela kufuneka kugqitywe ngokubanzi ngosuku olufanayo.

Iimpawu zoxinzelelo lwe-torsional shear high-strength bolts ziyafana nezo zebolts zamandla aphezulu ngokubanzi, ngaphandle kokuba indlela yokufaka i-pretension kukulawula ixabiso le-pretension ngokujija icandelo kwi-cut.Ukujijwa kwebholithi.

Uhlobo lwe-friction ye-bolt ephezulu yokudibanisa ixhomekeke ngokupheleleyo kwi-friction resistance phakathi kwezinto ezidityanisiweyo zokuhambisa amandla, kwaye ukuxhathisa ukukhuhla akukona nje ukuqiniswa kwangaphambi kokuqina kwebholi, kodwa kunye nepropathi echasene ne-skid ye-friction surface. igqitywe ngonyango olungaphezulu.Izinto eziphathekayo zokudibanisa kunye nomphezulu wokudibanisa.i-coefficient.

Emva kokuyifunda, ndiyakholelwa ukuba wonke umntu uye waqonda ngokusisiseko, apho kufuneka kusetyenziswe iibholiti eziphezulu, kunye nokusebenza okuchanekileyo kunye nokuqiniswa.