Igama lemveliso: Hex Socket Head Bolt

Ubungakanani: M3-M100

Ubude: 10-5000mm okanye njengoko kufuneka

IBakala: 4.8 6.8 8.8 10.9 12.9 14.9

Intsimbi yezinto eziphathekayo: Intsimbi/35k/45/40Cr/35Crmo

Umphezulu: Mnyama, Zinc Plated

Umgangatho : DIN912, ASTM A574

Isiqinisekiso: ISO 9001

Isampulu: Iisampuli zasimahla

Ukusetyenziswa: Izakhiwo zentsimbi, imigangatho emininzi, isiseko sentsimbi esiphakamileyo, izakhiwo, izakhiwo zemizi-mveliso, indlela ephezulu, umzila kaloliwe, umphunga wentsimbi, inqaba, isikhululo samandla kunye nezinye izakhelo zeworkshop yokwakha.

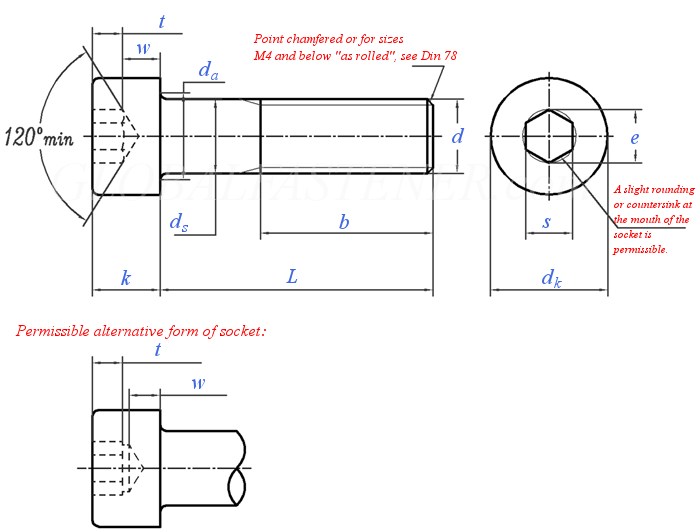

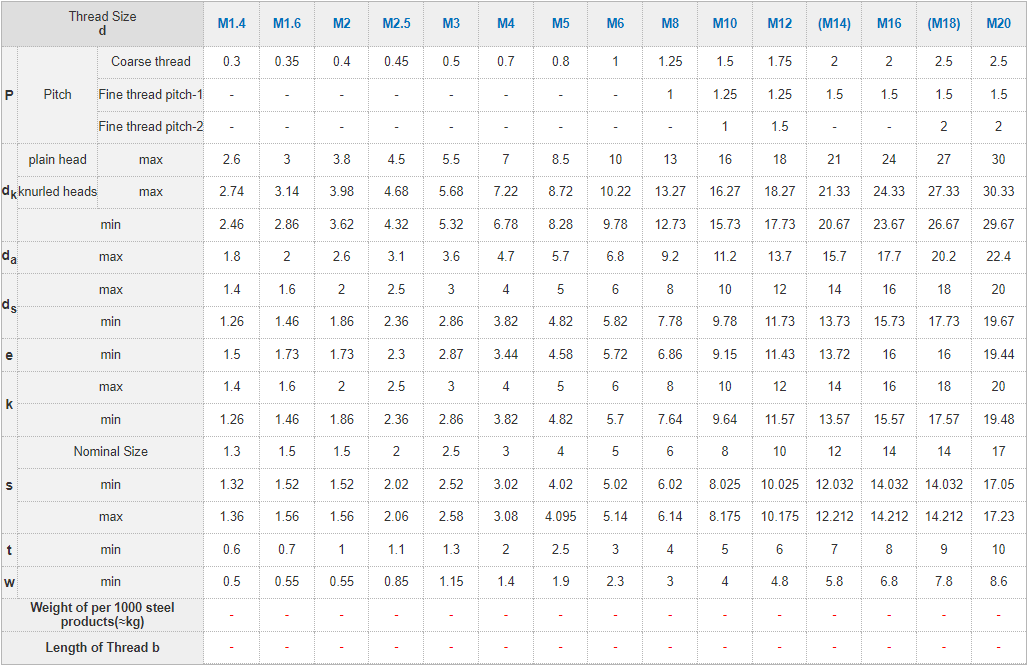

DIN 912 - 1983 Hexagon socket head cap izikrufu

① Ubungakanani ≤ M4, inqaku akufuneki litshiswe.

② e min = 1.14 * S min

④ Ubude obuqhelekileyo obungaphezulu kwe-300 mm buya kuba kumanyathelo angama-20 mm.

⑤ Lb ≥ 3P (P:Isandi somsonto orhabaxa)

⑥ Izinto:

a) Steel, iklasi Property: ≤M39: 8.8,10.9,12.9;> M39: njengoko kuvunyelwene.I-DIN esemgangathweni ye-ISO 898-1

b) steel stainless, iklasi Property: ≤M20: A2-70,A4-70;> M20≤M39: A2-50, A4-50;≤M39: C3;> M39: njengoko kuvunyelwene.Umgangatho we-ISO 3506, i-DIN 267-11

c) Isinyithi esingenantsimbi nge-DIN eqhelekileyo 267-18

Kutheni iindawo ezininzi zithanda ukusebenzisa izikrufu ze-hexagon socket, zilungele ntoni?

Into ebizwa ngokuba yi-hexagon socket bolt ibhekiselele kwintloko yesilinda enemilo yesokethi yehexagon, ekwaziyo ukubizwa ngokuba sisikrufu sentloko yesokethi yehexagon, isikrufu sesokethi yehexagon kunye nesikrufu sosokhethi esinehexagon.

Kutheni ihexagon, hayi ezine okanye ezintlanu?

Abantu abaninzi banemibuzo kwakhona, kutheni le nto uyilo kufuneka lube nehexagonal endaweni yezine, ezintlanu okanye ezinye iimilo?Isikrufu esine-hexagonal sinokujikwa ngama-60 ° ukubuyisela imizobo.Ukuba indawo incinci, i-screw ingafakelwa ixesha elide ukuba i-wrench inokuguqulwa ngama-degrees angama-60, okuyimveliso yokudibanisa phakathi kwe-angle yokujikeleza kunye nobude becala.

Ukuba isikwere, ubude becala bubude ngokwaneleyo, kodwa kufuneka bujikwe kwii-degrees ezingama-90 ukubuyisela umzobo, ongafanelekanga ukufakwa kwendawo encinci;ukuba i-octagon okanye i-decagon, i-angle ye-graphic restoration encinci, kodwa ubude becala lomkhosi buncinci.Ewe, kulula ukujikeleza.

Ukuba sisikrufu esinamacala anamanani angaqhelekanga, amacala amabini esikrufu awahambelani.Kwimihla yangaphambili, kwakukho izikrweqe ezimile okwefolokhwe kuphela, kwaye intloko ekrwada enamacala angaqhelekanga yayiyimbombo emile okwexilongo, eyayibonakala ingafanelanga ukusebenzisa amandla.

ihexagon socket ubulukhuni kunye neempawu

Ngokubanzi, iibholiti zentloko ze-hexagon ezixhaphakileyo ngamabakala angama-4.8, amabakala angama-8.8, amabakala angama-10.9, angama-12.9 njalo njalo.Ngokuqhelekileyo, amabakala ahlukeneyo eentloko ze-hexagon socket head bolts zikhethwa ngokweemfuno ezahlukeneyo, ukwenzela ukuba ukusebenza kweebholiti kunokuba luncedo ngakumbi.Namhlanje, i-Jinshang.com iya kuthetha nawe malunga namanqanaba obunzima be-hexagon socket bolts.

Ibakala lobulukhuni

Iibholiti zentloko ye-hexagon zihlelwa ngokobulukhuni be-screw force, amandla okuqina, amandla emveliso, njl., oko kukuthi, inqanaba leebholiti zentloko ye-hex socket, kwaye yintoni inqanaba le-hex socket bolts.Izixhobo ezahlukeneyo zeemveliso ziyafuneka ukuze zibe namabakala ahlukeneyo eebholiti zentloko zehexagon ezihambelana nazo.

Iibholiti zentloko ze-hexagon zentloko zohlulwe zibe ziqhelekileyo kunye namandla aphezulu ngokwamandla ebakala.Iibholiti zentloko zesokhethi eziqhelekileyo zibhekisela kwibakala lesi-4.8, kwaye iibholithi zesokethi ezomeleleyo zibhekisela kumabakala 8.8 nangaphezulu, kuquka ibakala 10.9 nele-12.9.IBanga le-12.9 izikrufu zesocket zehexagon zentloko zibhekisa kwizikrufu zentloko ezigqunywe ngeoyile.

Umgangatho wokusebenza we-hexagon socket head cap bolts yokudibanisa isakhiwo sentsimbi yahlulwe ibe ngamabakala angaphezu kwe-10 afana ne-3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, njl., apho amabanga 8.8 nangaphezulu anjalo. ngokudibeneyo ebizwa ngokuba ziibholiti eziphezulu, kwaye iibholiti zenziwe ngentsimbi ephantsi ye-carbon Alloy okanye i-medium carbon steel kunye nonyango lobushushu, ezinye zibizwa ngokuba ziibholiti eziqhelekileyo.Ileyibhile yomgangatho wokusebenza webholithi iqulathe iinxalenye ezimbini zamanani, ezimele ixabiso lamandla okuqina kunye nomlinganiselo wesivuno semathiriyeli yebholi ngokulandelelanayo.

Iklasi yokusebenza

Ileyibhile yomgangatho wokusebenza webholithi iqulathe iinxalenye ezimbini zamanani, ezimele ixabiso lamandla okuqina kunye nomlinganiselo wesivuno semathiriyeli yebholi ngokulandelelanayo.

Iibholithi zodidi lwentsebenzo 4.6 zithetha:

1. Amandla okuzinza okubizwa ngokuba yi-bolt material afikelela kwi-400MPa;

2. Umlinganiselo wamandla esivuno sempahla ye-bolt ngu-0.6;amandla okuvunwa okuqhelekileyo kwesixhobo sebholithi yi-400×0.6=240MPa.

Inqanaba lokusebenza 10.9 iibholiti zamandla aphezulu, emva kokunyangwa kobushushu, zinokufikelela:

1. Amandla okuzinza okubizwa ngokuba yi-bolt material afikelela kwi-1000MPa;

2. Umlinganiselo wamandla esivuno se-bolt material ngu-0.9;amandla emveliso yegama lesixhobo sebholithi yi-1000×0.9=900MPa.

Intsingiselo yomgangatho wokusebenza wehexagon socket bolts ngumgangatho wamazwe ngamazwe.Iibholiti zebakala elifanayo lentsebenzo, kungakhathaliseki ukuba umehluko kwizinto eziphathekayo kunye nemvelaphi, zisebenza ngokufanayo, kwaye kuphela ibakala lokusebenza elinokukhethwa kuyilo.

Amabanga ahlukeneyo anamaxabiso ahlukeneyo kwimarike.Ngokubanzi, ixabiso leebholiti zentloko yesokethi ephezulu yokuqina ngokuqinisekileyo liphezulu kakhulu kunelo leebolt zentloko zesokethi eziqhelekileyo.Kwimarike, eyona nto isetyenziswa ngokuqhelekileyo yi-4.8, 8.8, 10.9, kunye ne-12.9.I-Zonolezer okwangoku ibonelela ngezikrufu zentloko yesokethi kumabanga4.8,6.8,8.8, 10.9, 12.9, kunye ne-14.9.

Izinto ezilungileyo zokusebenzisa iibholiti zesokethi ezinehexagon

1. Inokumelana nemithwalo emikhulu.

Inemigangatho emithandathu ethwala amandla, ekwaziyo ukumelana nesikrufu kunezikrufu ezisicaba kunye nezikrufu ezimilise okwesiphambano ezinemigangatho emibini kuphela.

2. inokungcwatywa isetyenziswa.

Oko kukuthi, i-nut yonke ifakwe kwi-workpiece, enokuthi igcine umphezulu we-workpiece egudileyo kwaye intle.

Ikhava ye-GIF

3. Kulula ukuyifaka.

Xa kuthelekiswa nesikrufu se-hexagon yangaphandle, ihexagon yangaphakathi ifanelekile kwizihlandlo ezininzi zokuhlanganisa, ngakumbi kwizihlandlo ezimxinwa, ngoko kulungele kakhulu ukudibanisa kunye nokugcina, kwaye kukulungele ukulungisa.

4. Akukho lula ukuqhaqha.

Izixhobo esiqhele ukuzisebenzisa zizitshixo ezilungelelanisiweyo, izikrurudrayiva kunye nezikrweqe ezifileyo, njl. njl., kwaye iintsimbi ezikhethekileyo kufuneka zisetyenziswe ukususa iibholiti zesokethi zehexagon.Ngoko ke, akulula ukuba abantu abaqhelekileyo bawuqhawule.Ngokuqinisekileyo, ukuba uyakhuphisana, unokuyila zonke iintlobo zezakhiwo ezingaqhelekanga.Umbuzo kukuba ingaba i-s