Igama lemveliso: Welding Nuts

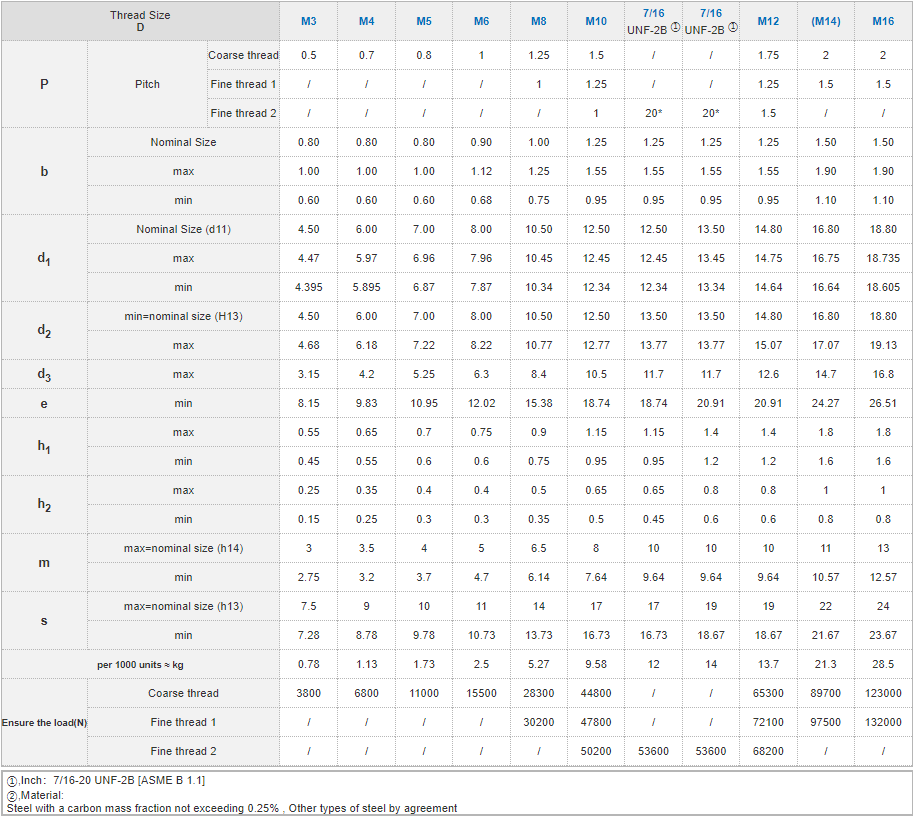

Ubungakanani: M8-M24

IBakala: 6.

Intsimbi yezinto eziphathekayo: Intsimbi/35k/45/40Cr/35Crmo

Umphezulu: Ithafa, iZinc iPlated

Umgangatho: DIN928, DIN929

Xa kuthelekiswa namantongomane aqhelekileyo, i-welding nuts ifaneleke ngakumbi kwi-welding.Ngokuqhelekileyo zenziwe ngezinto ezidibanisayo kwaye zityebile kwaye zilungele ukuwelda.I-Welding ilingana nokuguqula iinxalenye ezimbini ezihlukeneyo zibe yinto yonke, inyibilika isinyithi kwiqondo lokushisa eliphezulu kunye nokuxuba.Emva kokupholisa phantsi kunye, ii-alloys ziya kongezwa phakathi, kwaye ingaphakathi liyimpembelelo yamandla eemolekyuli, kwaye amandla ngokuqhelekileyo mkhulu kunomzimba womzali.Uvavanyo lweeparamitha ze-welding kuxhomekeke kubungakanani be-fusion ye-weld, kwaye i-welding parameters ihlengahlengiswa ngokobungakanani be-fusion de iziphene zipheliswe.Ngokuqinisekileyo, umgangatho we-welding unxulumene nonyango lwangaphambili lwe-welding, njengokucoca, i-oil stains, njl. Ngoko ke, ukusetyenziswa kwamantongomane e-weld kuninzi kakhulu.Izilumkiso zokusebenzisa i-welding nuts: 1. Igesi yokukhusela i-argon.2. Ubude be-tungsten electrode ephuma kwi-nozzle yegesi.3. Ubude be-arc ye-welding kukhethwa ukuba i-2 ~ 4mm xa i-welding yentsimbi eqhelekileyo, kunye ne-1 ~ 3mm xa i-welding steel stainless.Ukuba lide kakhulu, umphumo wokukhusela awulungile.4. Ukuthintela umoya kunye nokungena komoya.Kwiindawo ezinomoya, qiniseka ukuba uthathe amanyathelo okuthintela inetha, kwaye uthathe amanyathelo afanelekileyo okungenisa umoya ngaphakathi.5. Sebenzisa unikezelo lwamandla kunye neempawu zangaphandle ezithe nkqo, kwaye usebenzise i-polarity epholileyo (ucingo luxhunywe kwi-pole negative) xa i-DC.6. Ngokuqhelekileyo ifanelekile ukuwelda kwamacwecwe amancinci angaphantsi kwe-6mm, kwaye ineempawu ezintle ze-welding seam shape kunye ne-welding deformation encinci.7. Ukuze kuthintelwe ukwenzeka kwe-welding pores, iindawo ze-welding kufuneka zihlanjululwe ukuba kukho i-rust, ukungcola kweoli, njl. Umgca ophakathi we-electrode ye-tungsten kunye ne-workpiece kwindawo ye-welding kufuneka igcine i-angle ye-80-85 °, kwaye i-angle phakathi kocingo lokuzalisa kunye nomphezulu we-workpiece kufuneka ibe yincinci kangangoko kunokwenzeka.Ngokuqhelekileyo malunga ne-10 °.

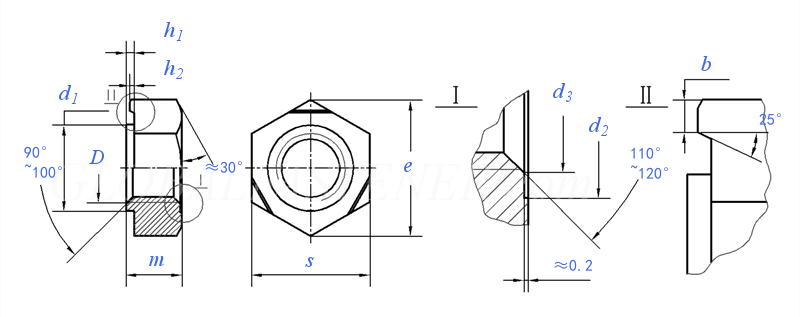

DIN 929 - 2013 Hexagon Weld Nuts